I initiated this focus module with no prior knowledge in the world of ceramics. Throughout this focus, I acquainted myself with a material entirely unfamiliar to me. In the first part of the semester, my efforts were dedicated to exploring ceramics and its possibilities. The focus was on learning from others and experimenting with a wide range of techniques.

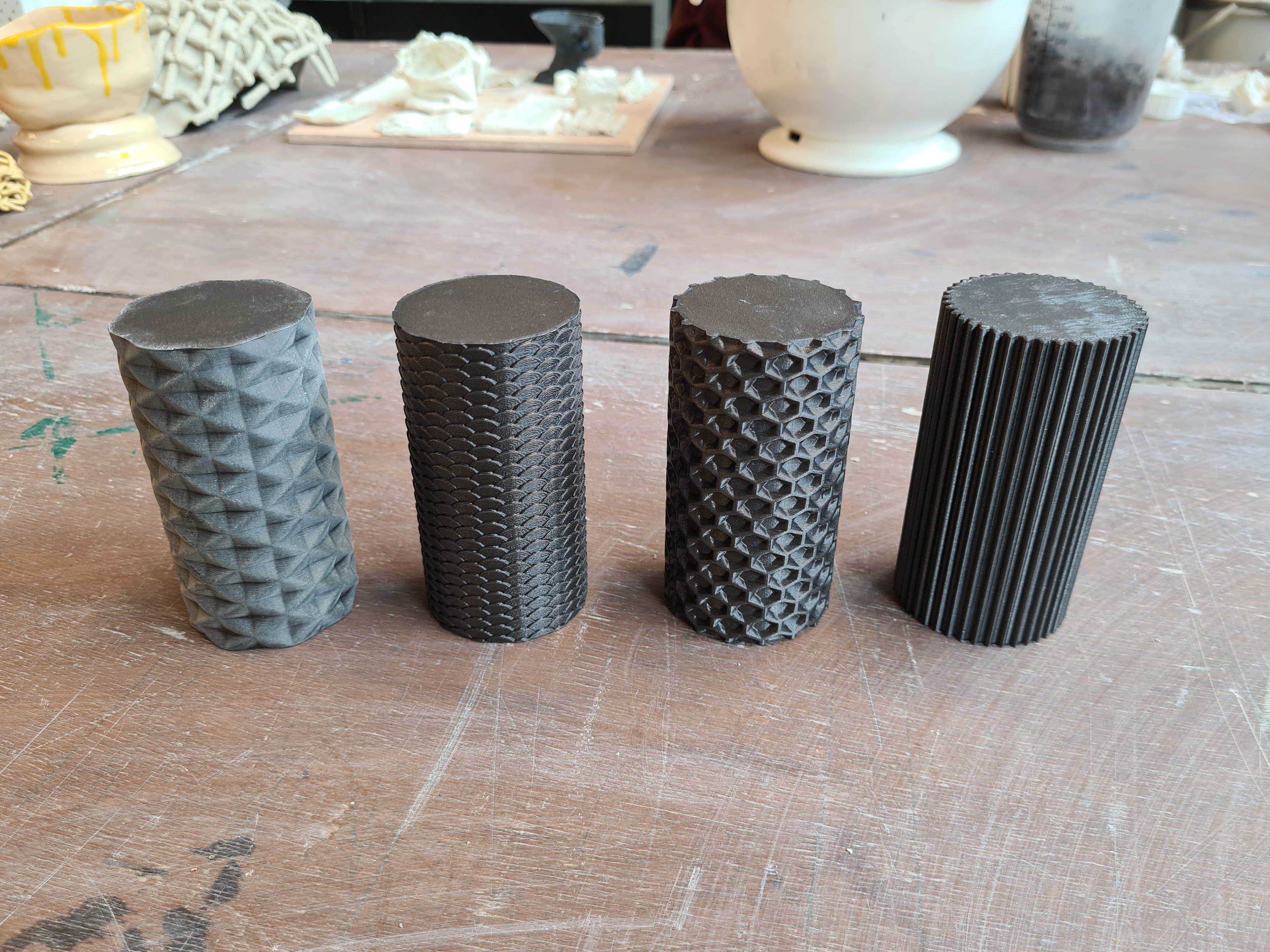

After acquiring a foundational knowledge, I challenged myself by integrating my own innovative approach with what I had learned about ceramics. I found the traditional method of creating a mold to be cumbersome and was determined to find a new, more straightforward way. To achieve this, I ventured into the for me familiar digital realm using Solidworks. My idea was to 3D print a master mold directly instead of printing an object and manually creating a mold for it. This eliminates the need for an original object, saving time as I don't have to work with clay in this phase. The success of my first test model using this method motivated me to further develop this and challenge myself to create this on a larger scale. I opted for a larger scale because ceramics present numerous challenges when executed on a grander scale.

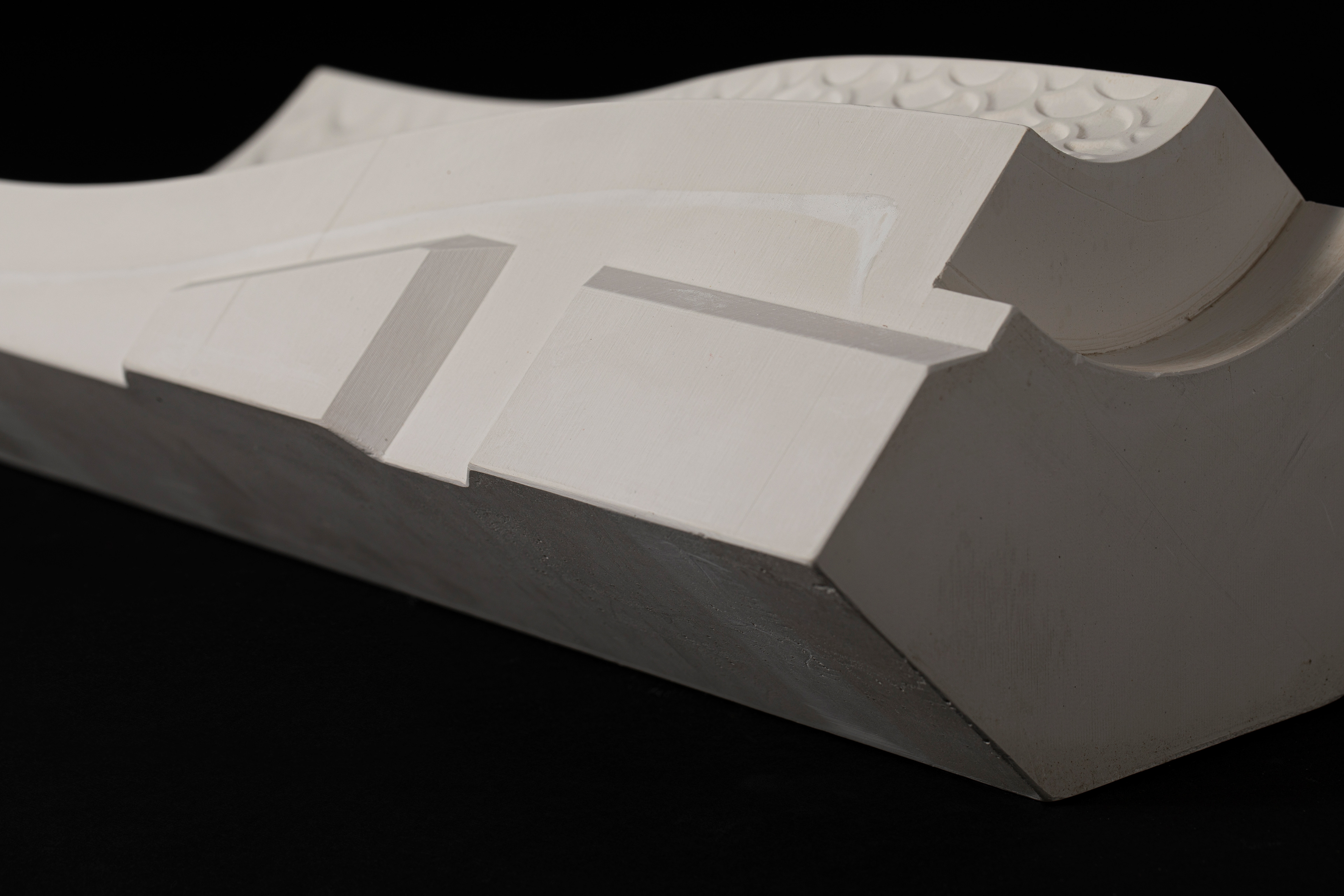

Modular Plaster Mold

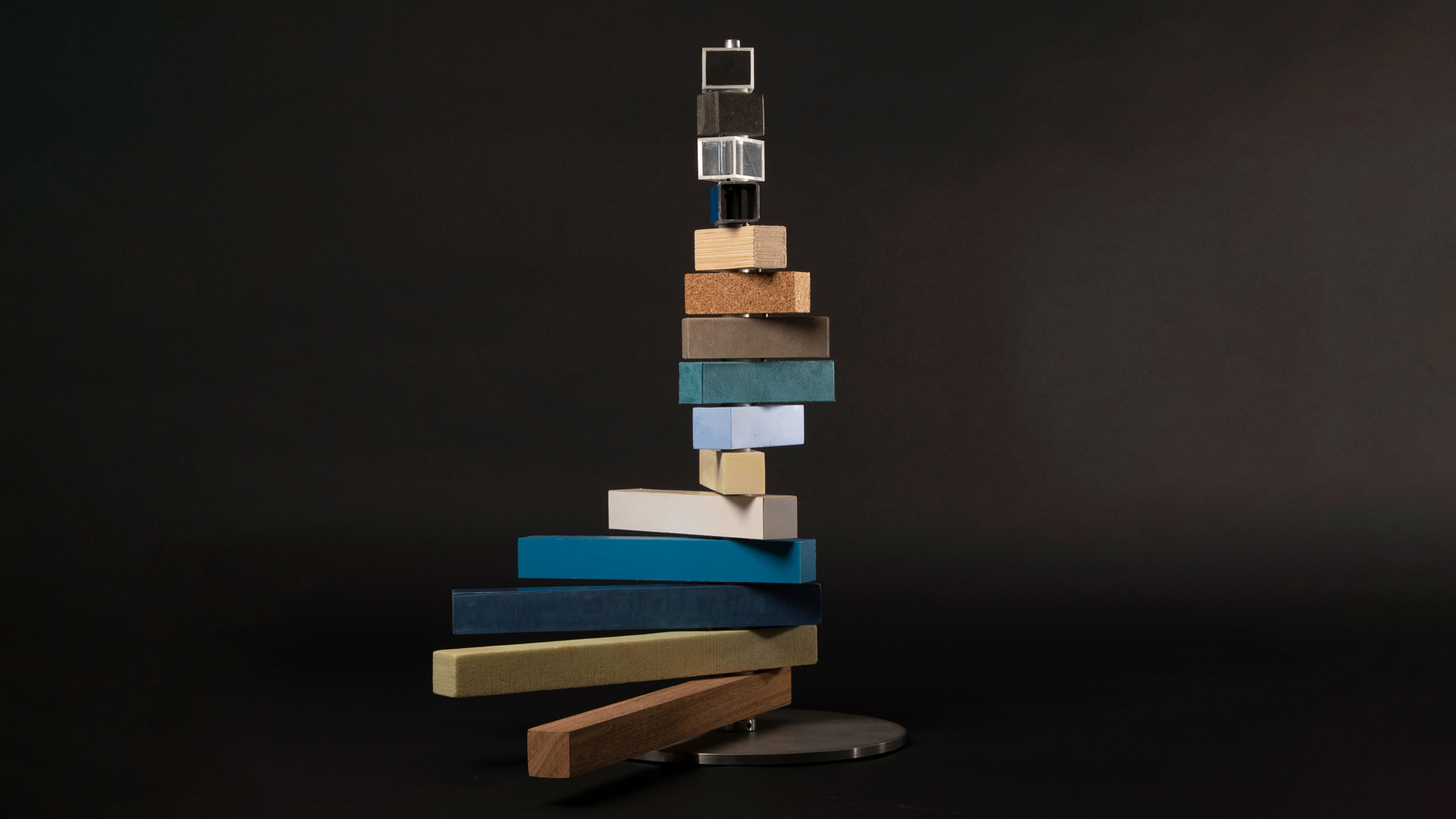

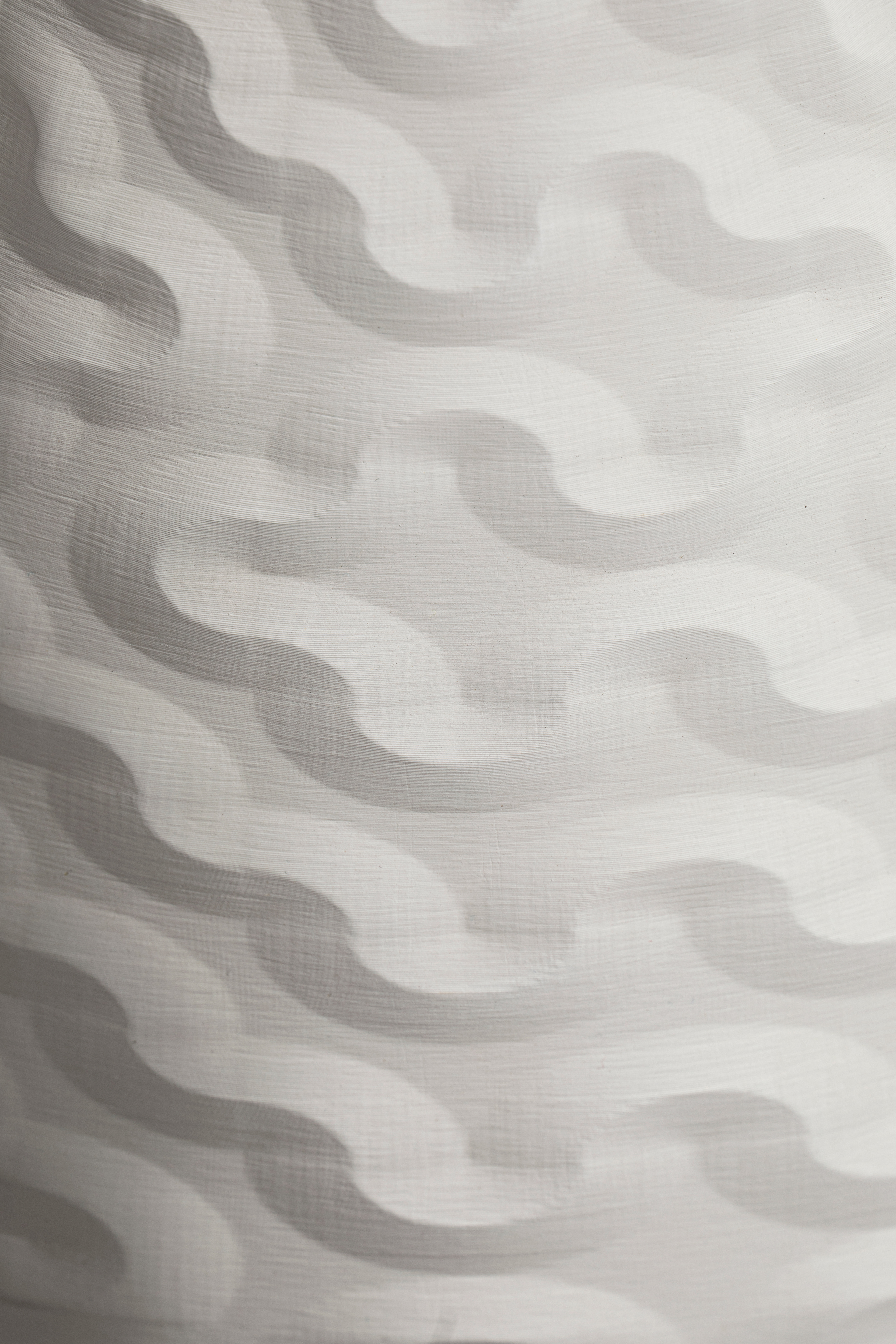

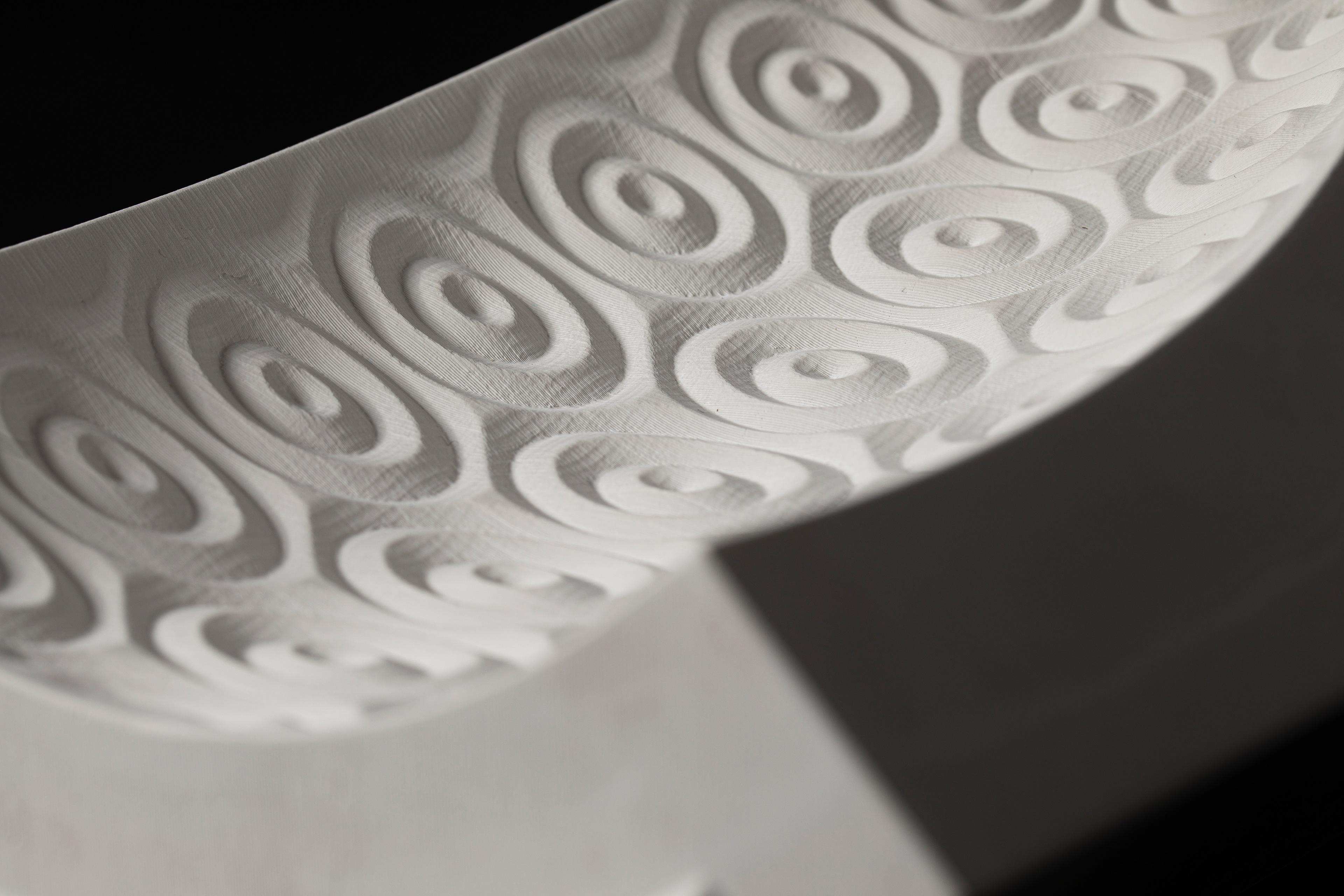

By combining my new mold-making technique with textures that fascinated me in the first part of the semester, a concept emerged that is nearly impossible to achieve in a traditional manner. I created a modular plaster mold consisting of five parts (one base and four side pieces) with a choice of eight different side pieces. Each mold part is universal, allowing them to interchange positions. I designed the textures by creating heightmaps in Adobe Illustrator and translating them into 3D in Solidworks. The texture collection combines geometric patterns with both regular and more random shapes. I brought my digital design to the physical world by 3D printing master molds and casting the mold parts in plaster.

Collaborating with the industry is essential to me. It's where I prefer to work, and significant changes can take place. I see potential within the industry for producing vases using this production method. My mold enables the creation of an extensive collection of unique vases with just a few mold parts. This allows for the relatively easy and affordable production of unique vases. Additionally, each mold part can be replaced individually if excessively worn, and new mold parts can be designed and added to the collection without having to replace the existing mold.

me presenting my work to Máxima Queen of the Netherlands

Photos taken by Gijs de Kort Fotografie

Photos During Presentation taken by Boudewijn Bollman