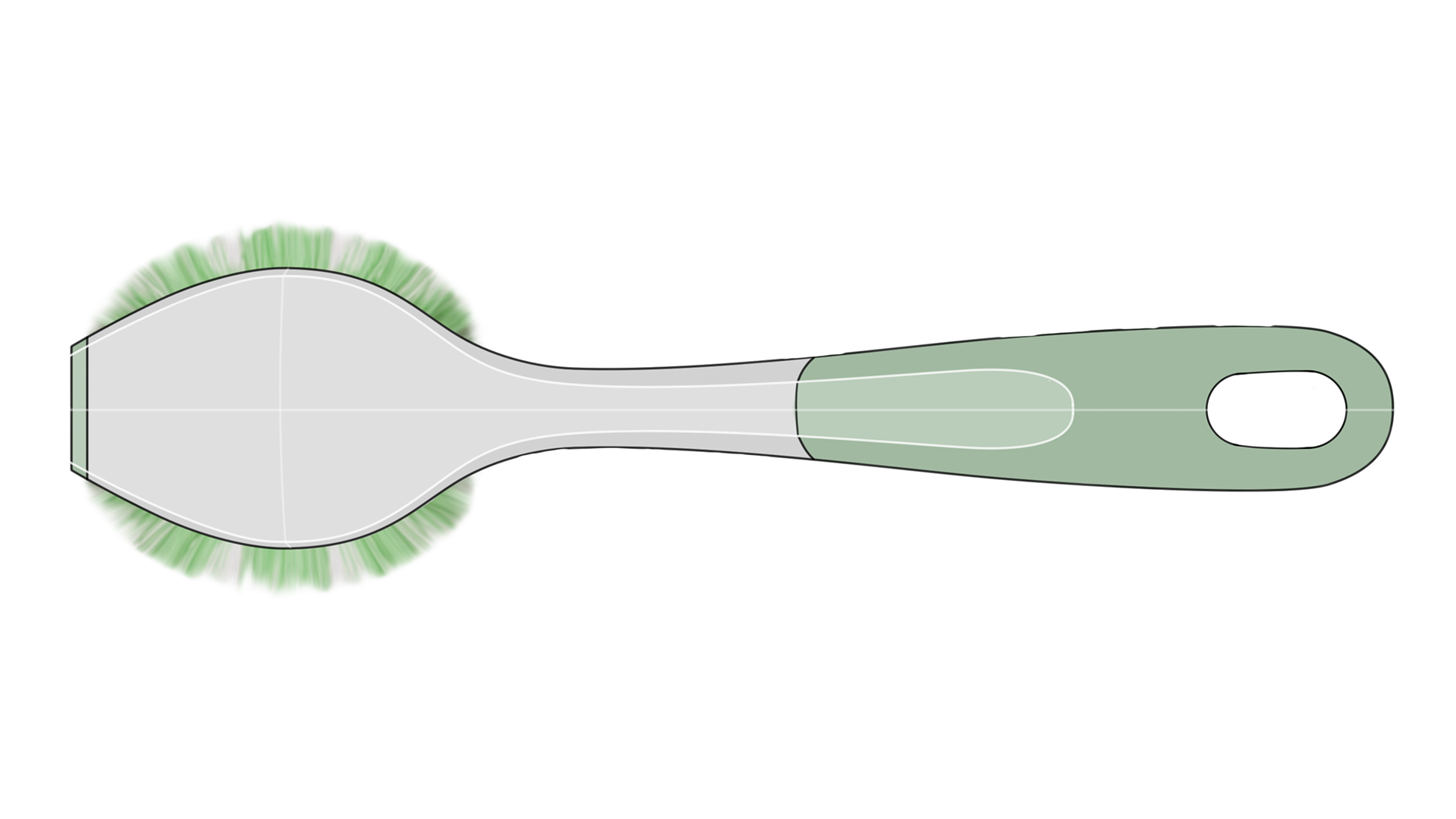

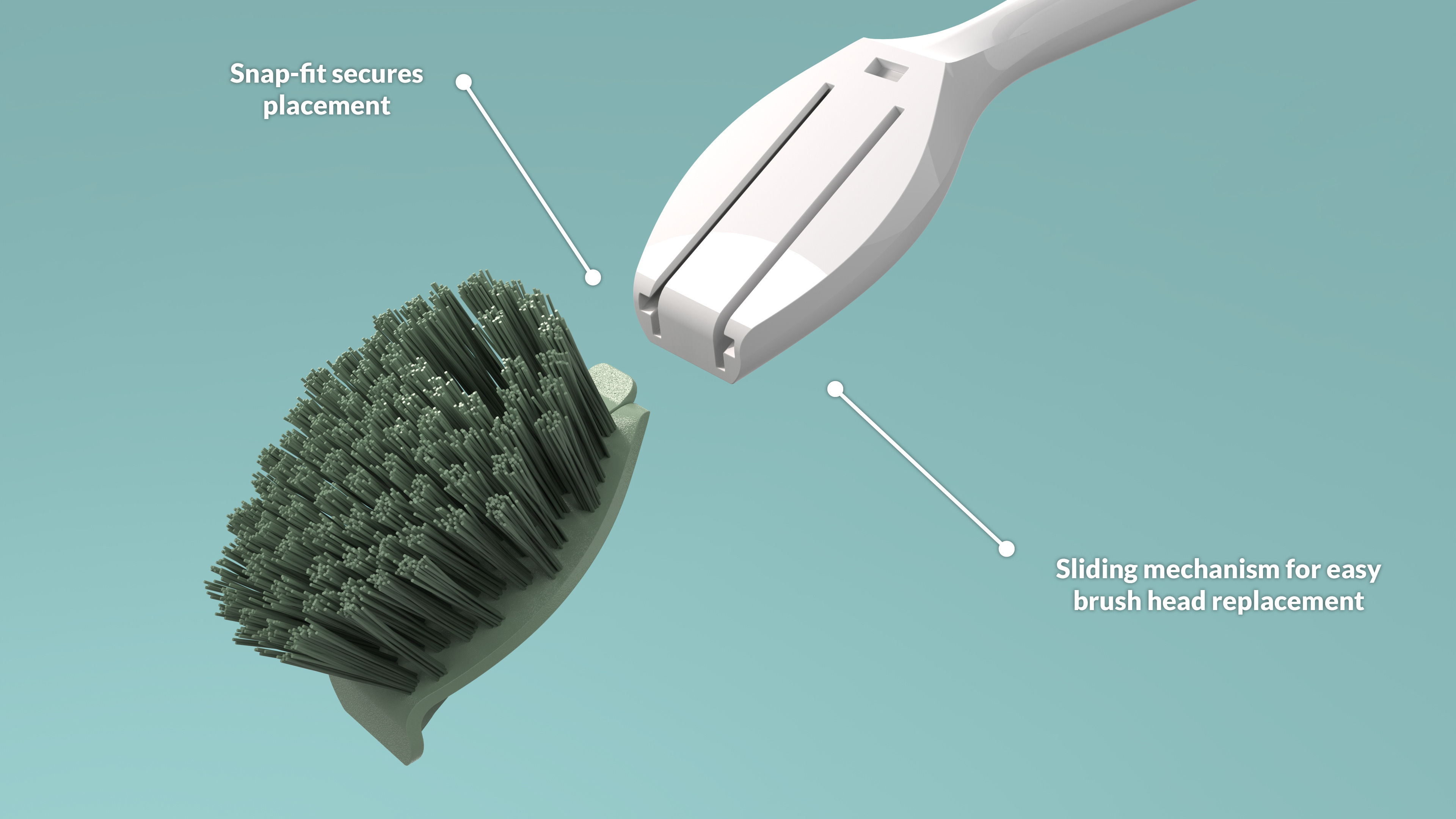

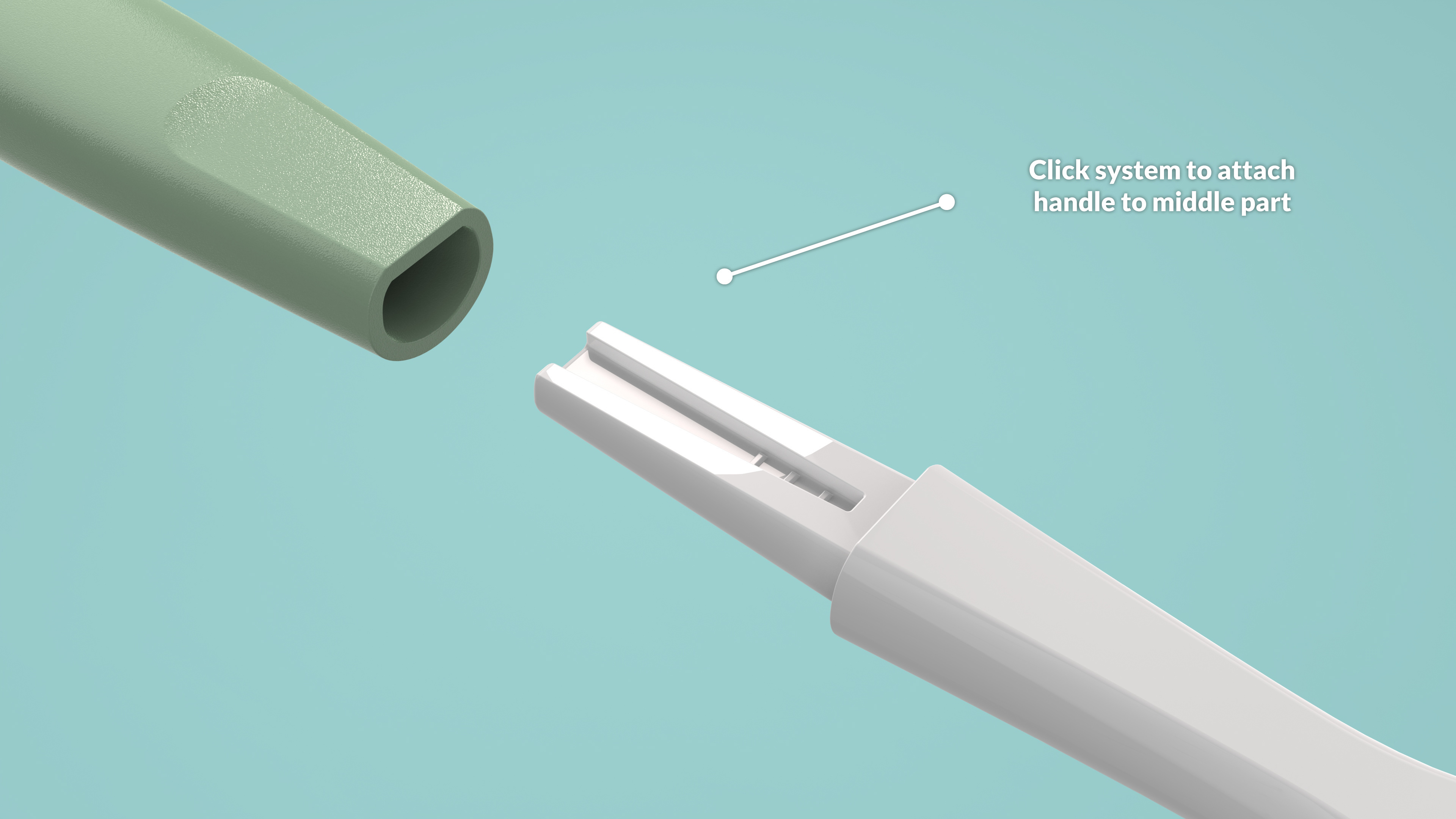

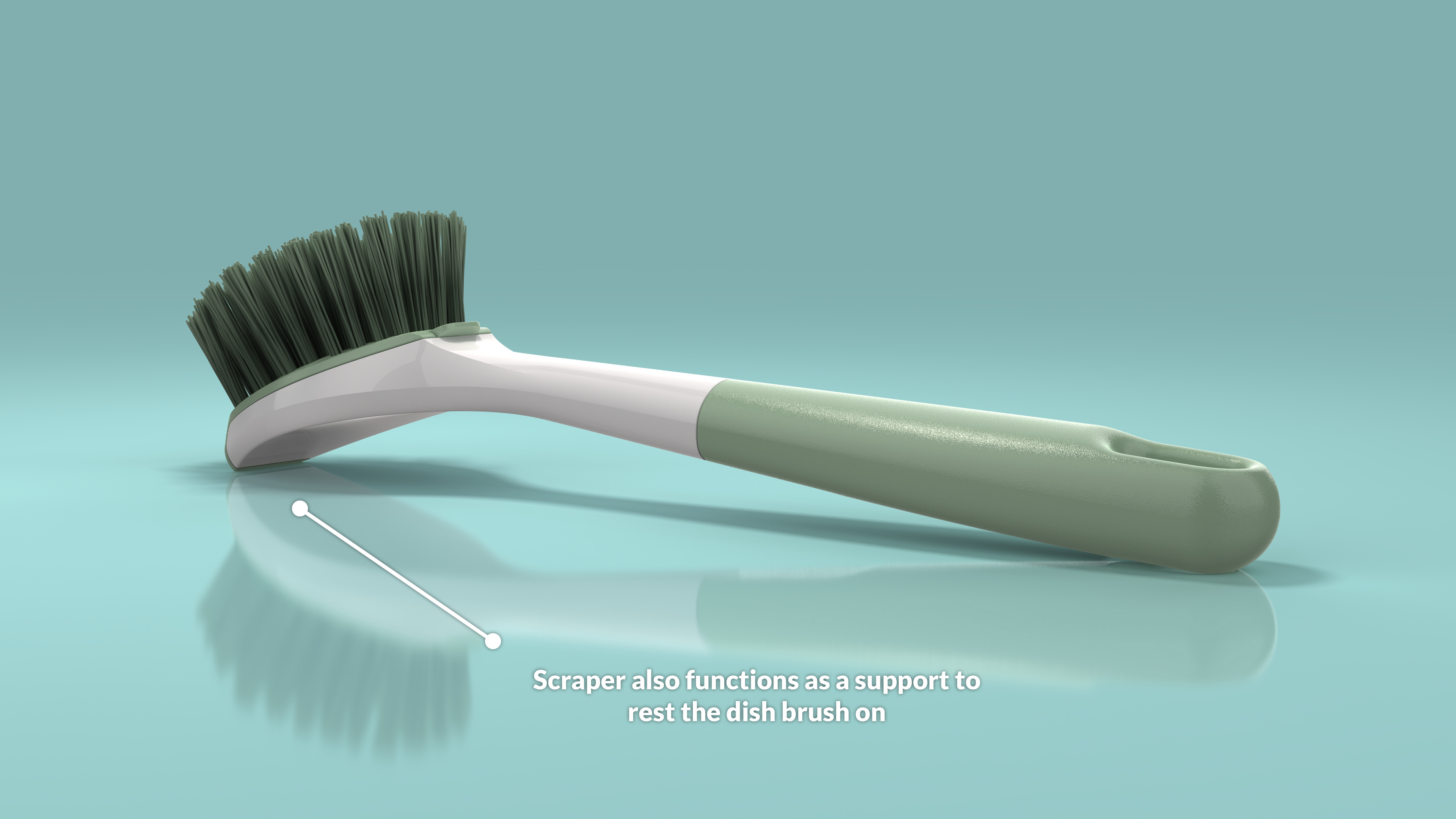

During my internship at GBO Innovation Makers I got the assignment to design a biodegradable consumer product. I chose to design a dish brush of which the wearing parts and the handle of the brush are separated. This way the biggest part of the dish brush (the handle) can be reused when the brush head needs replacement.

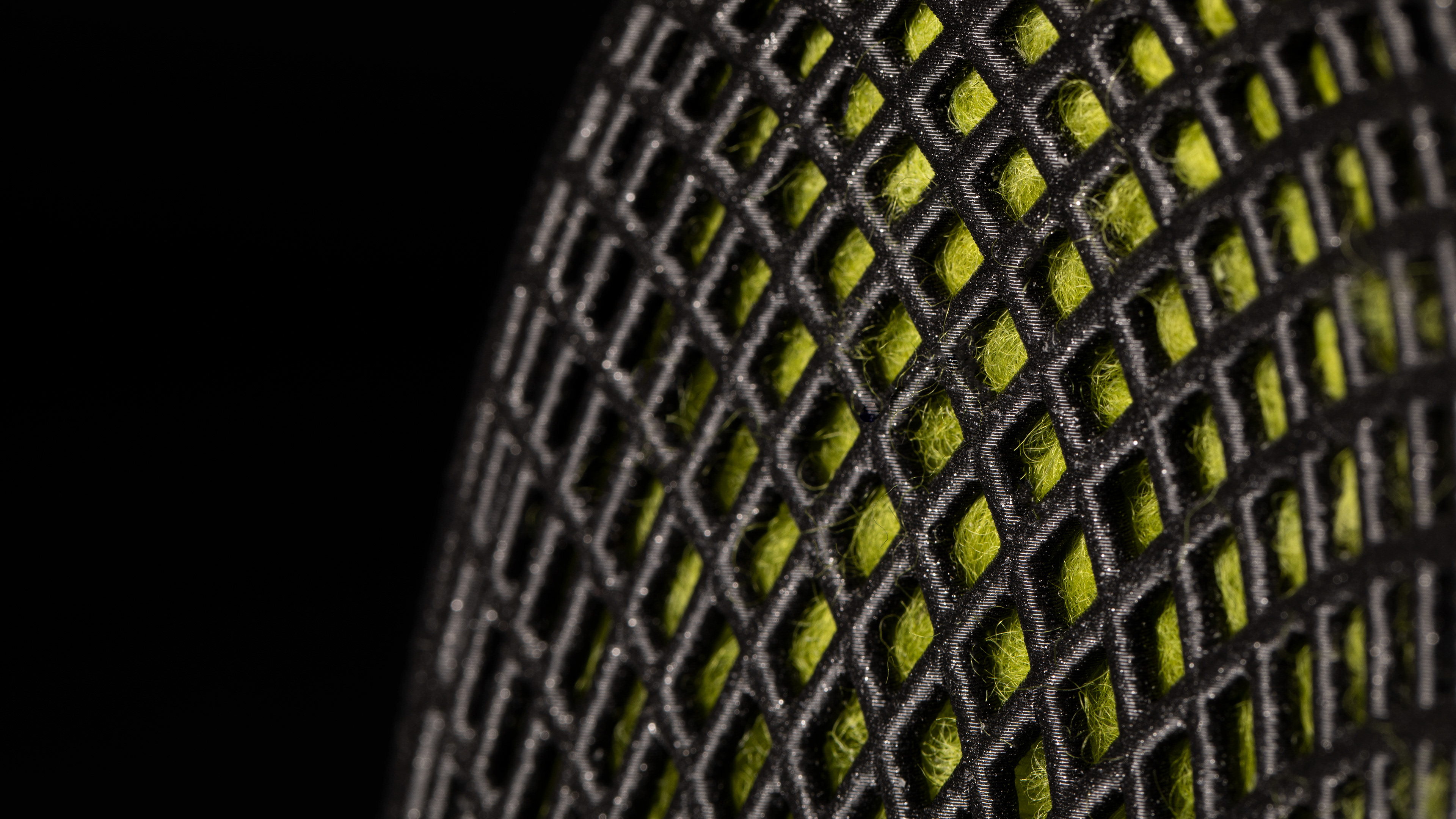

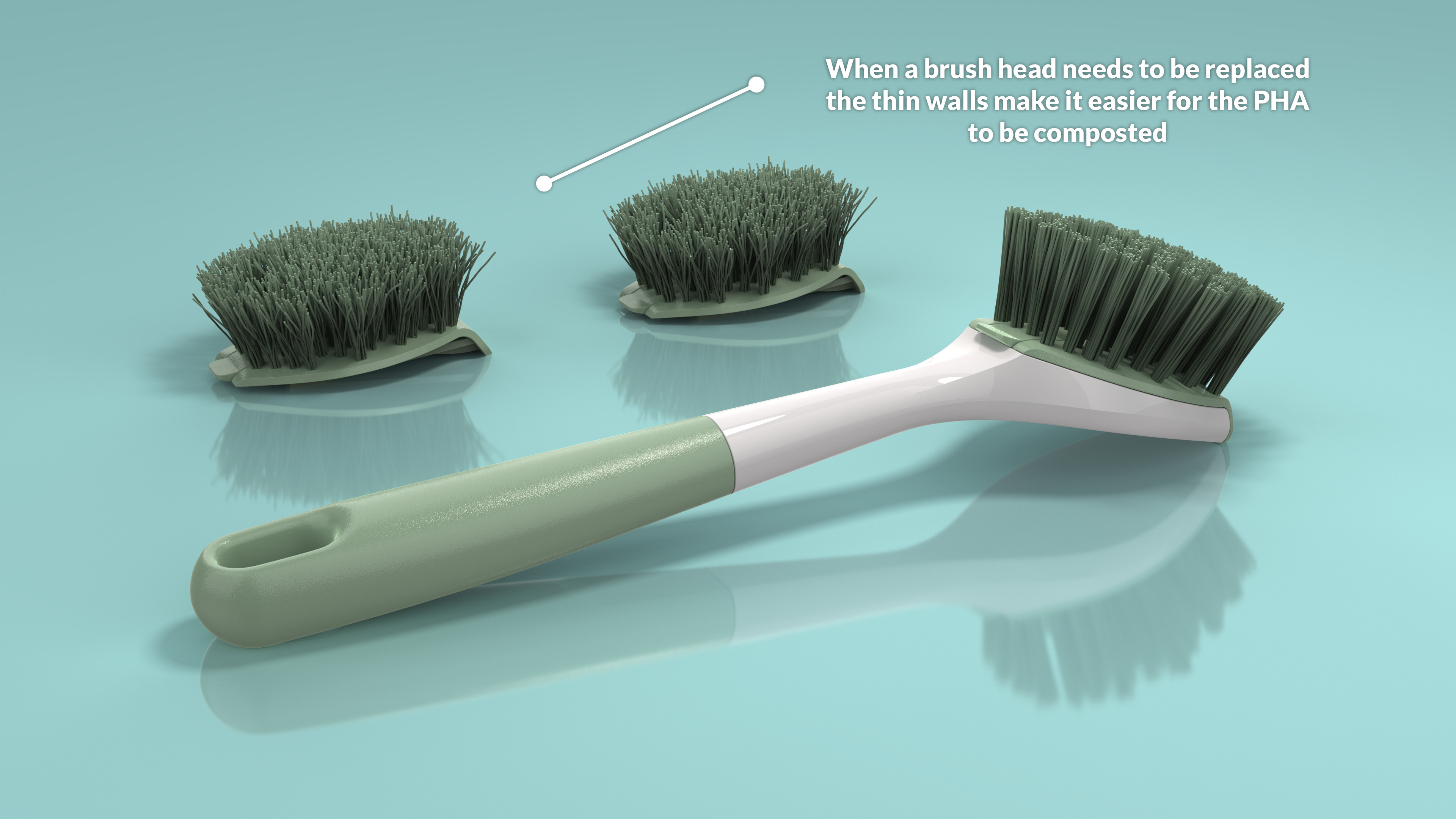

The dish brush will be completely made from PHA which is a relatively new truly biodegradable plastic. This plastic leaves no microplastics behind and does not dissolve in water but instead is eaten by bacteria. To speed up this process I gave the brush head thin walls.

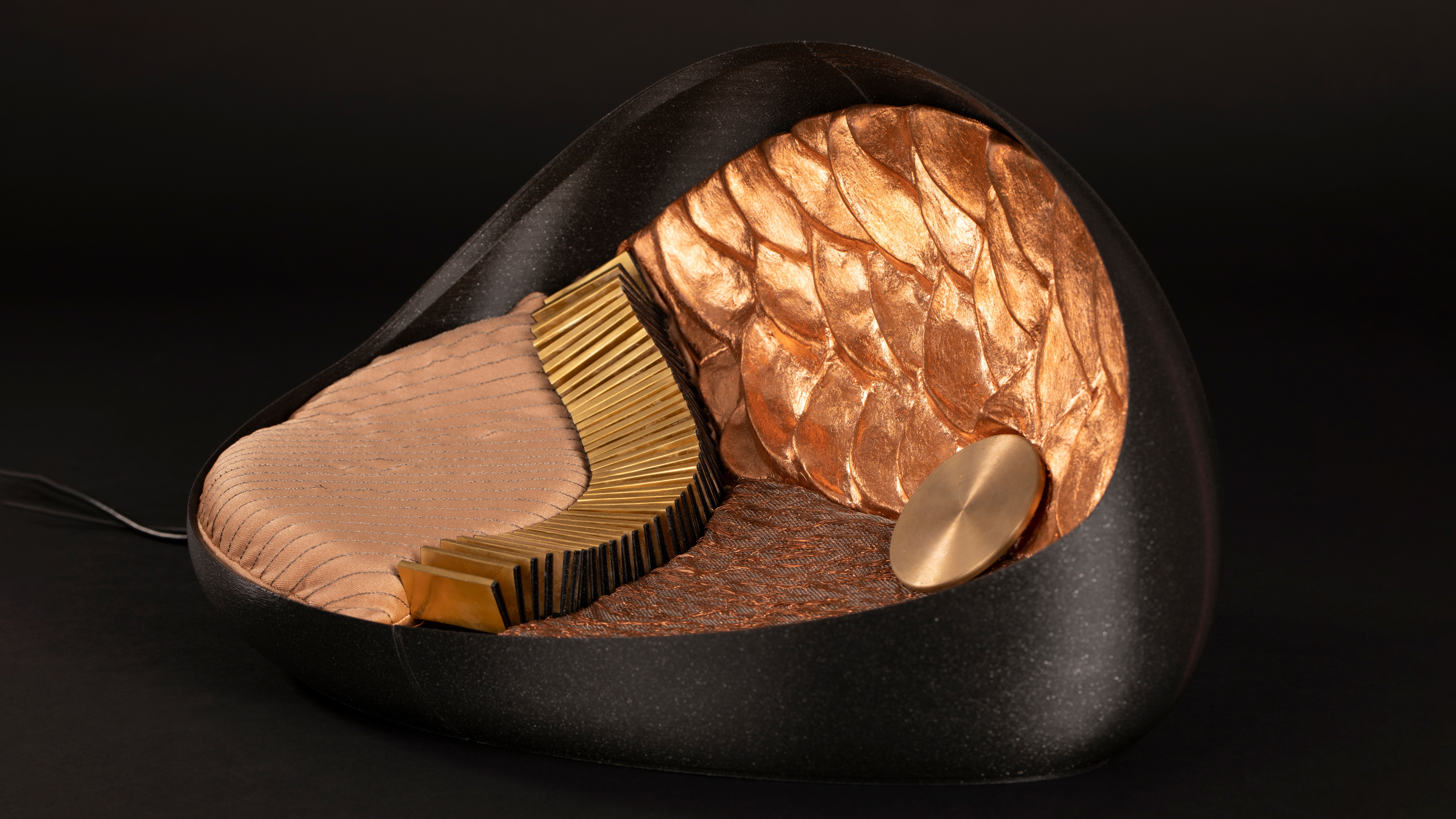

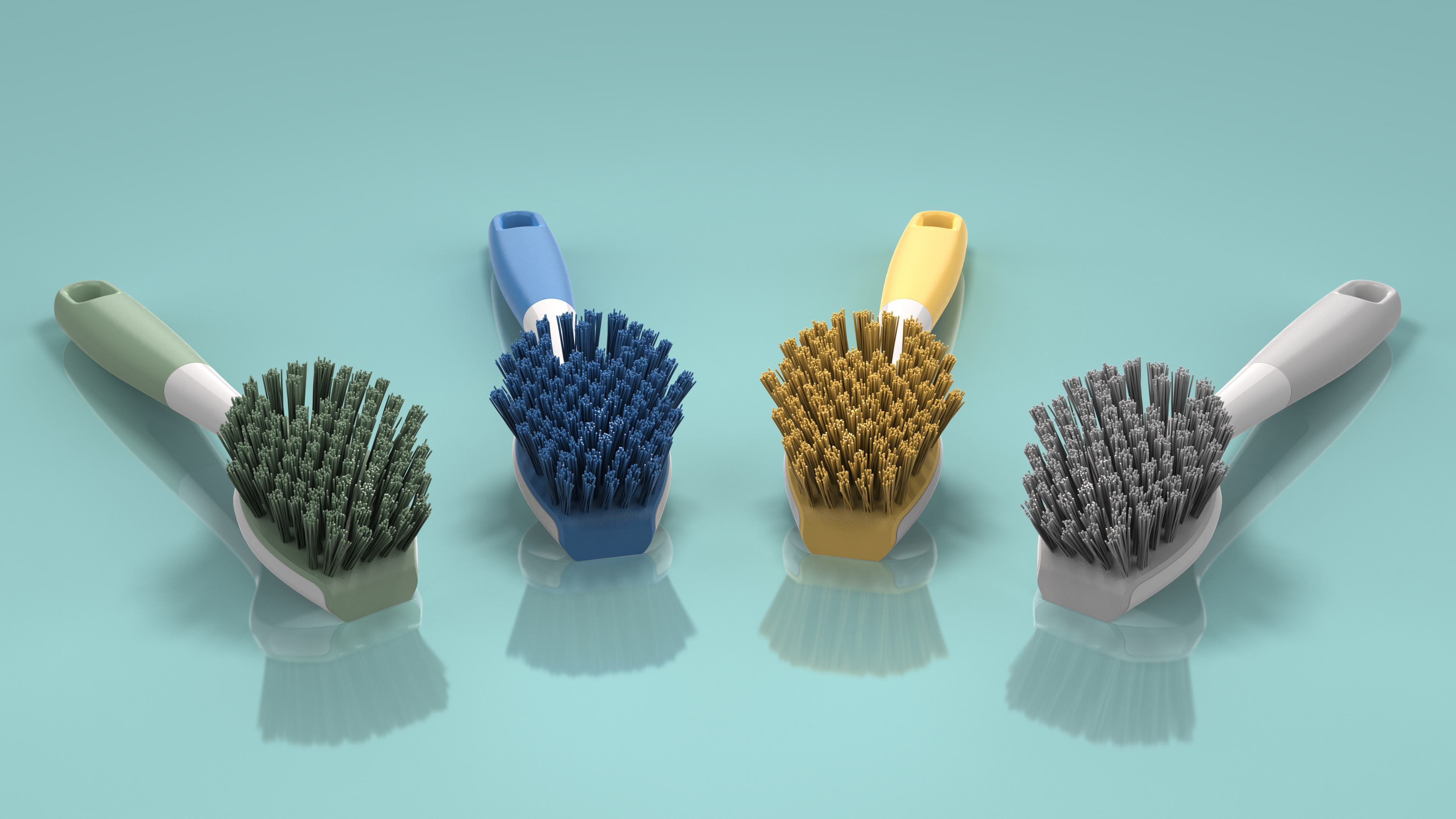

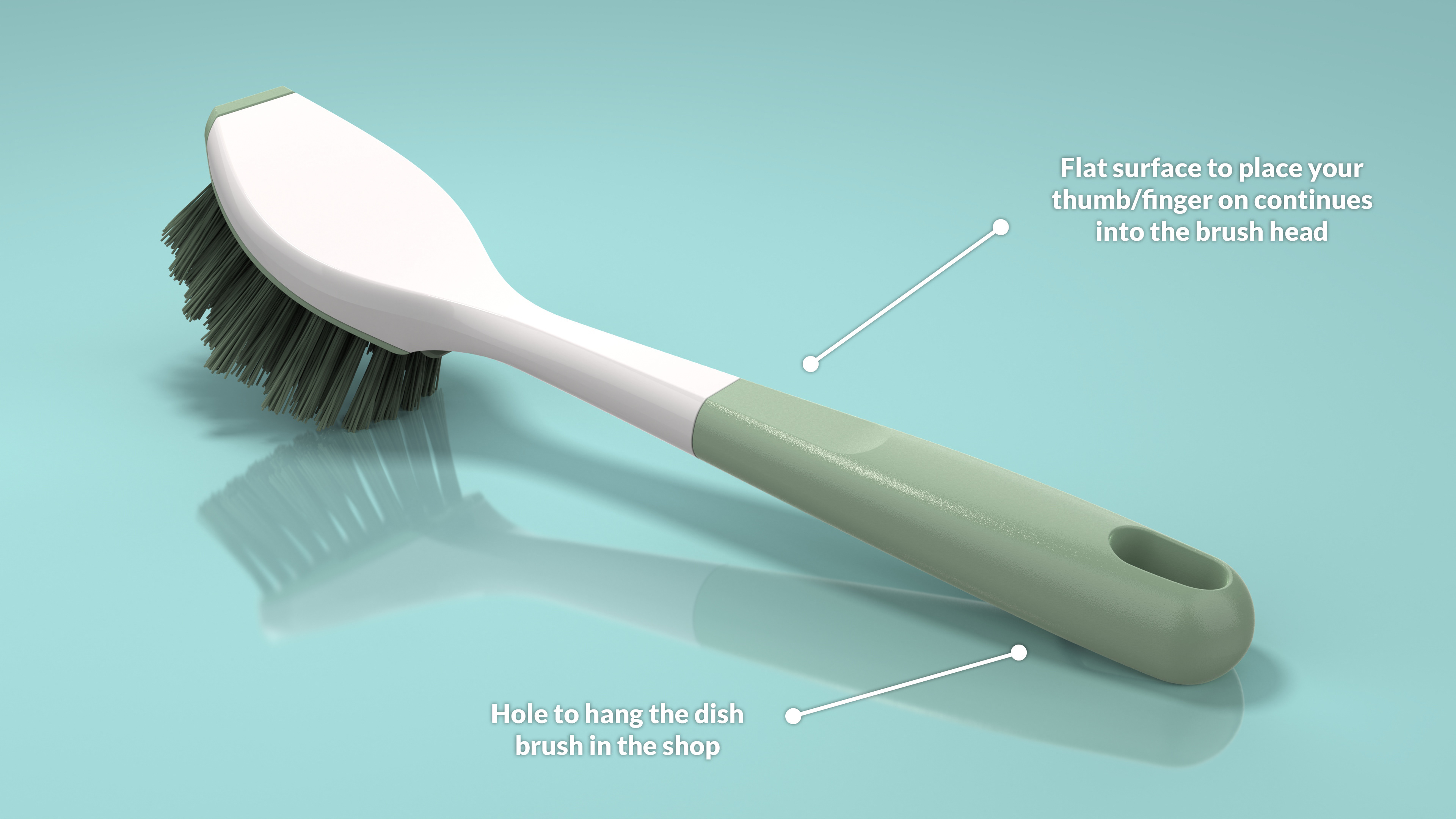

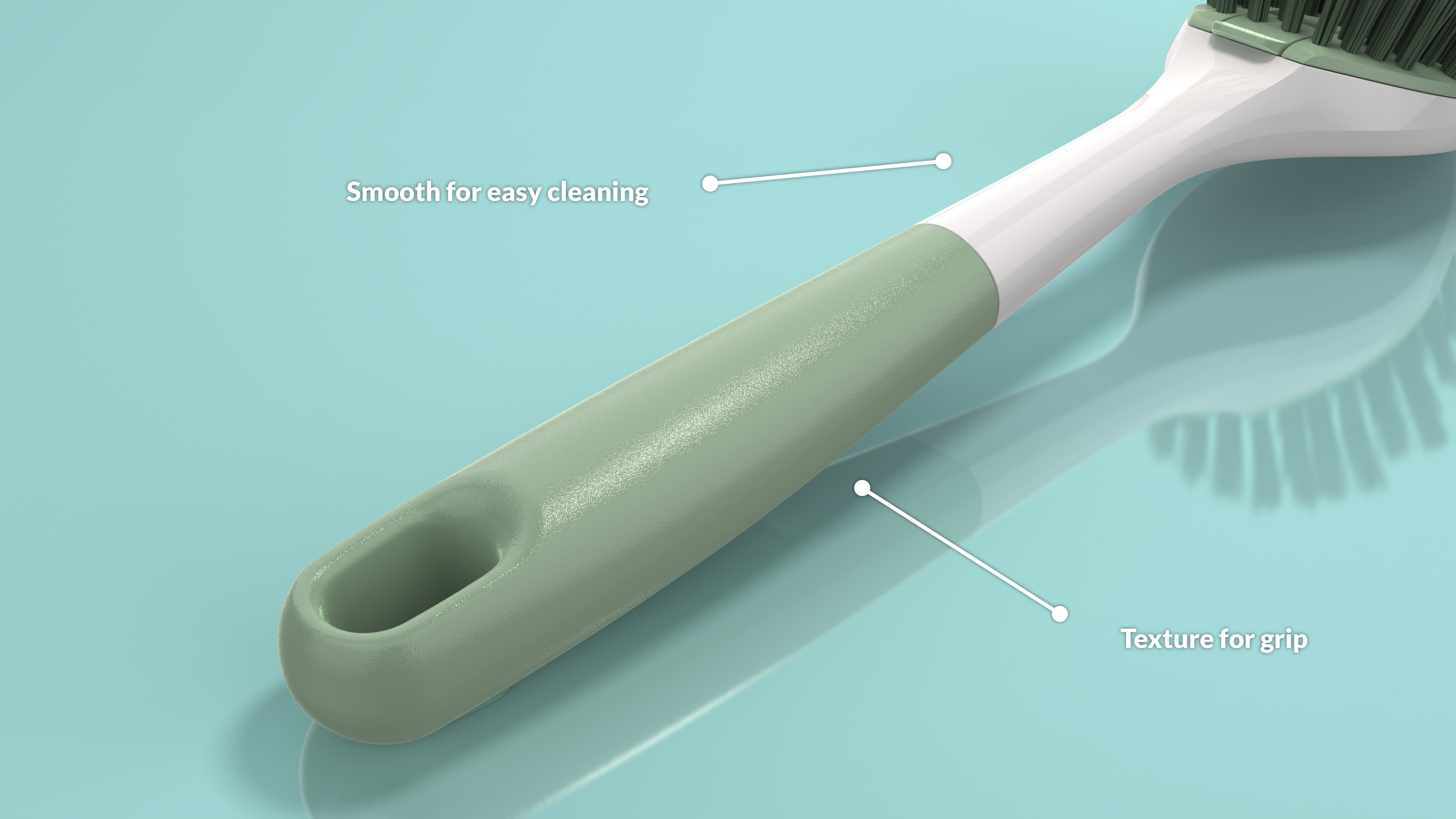

On this page you see a part of my process and the final renders I made.

WHY I designed a dish brush?

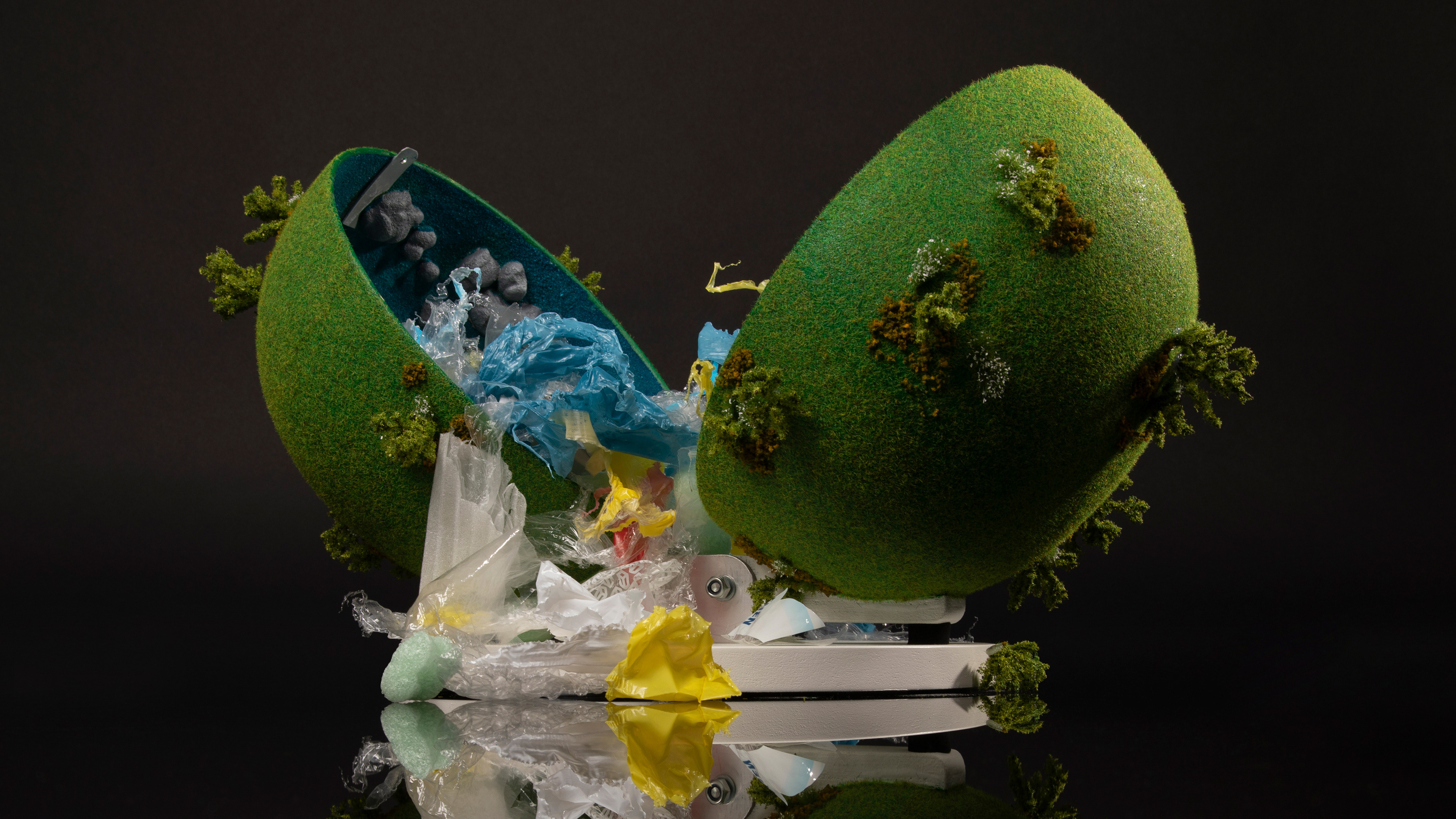

I have chosen to design a dish brush made of bioplastic, because a dish brush is a product that wears out. The microplastics that come off the dish brush end up in the water, the sewage system and eventually in the ocean. One of the strengths of PHA is that it does not Leave microplastics behind, thus solving this problem.

In addition, a dish brush is a plastic product that is regularly replaced in its entirety, while only a small part of the product actually needs to be renewed.

I made this project during my internship at GBO Innovation Makers